Welcome aboard to the our video site for sailors. We are being constantly blasted by scammers and pirates, so registration is invite only

contact@sailorsahoy.com with "Invite". No spam, no newsletters. Just a free account

শর্টস সৃষ্টি

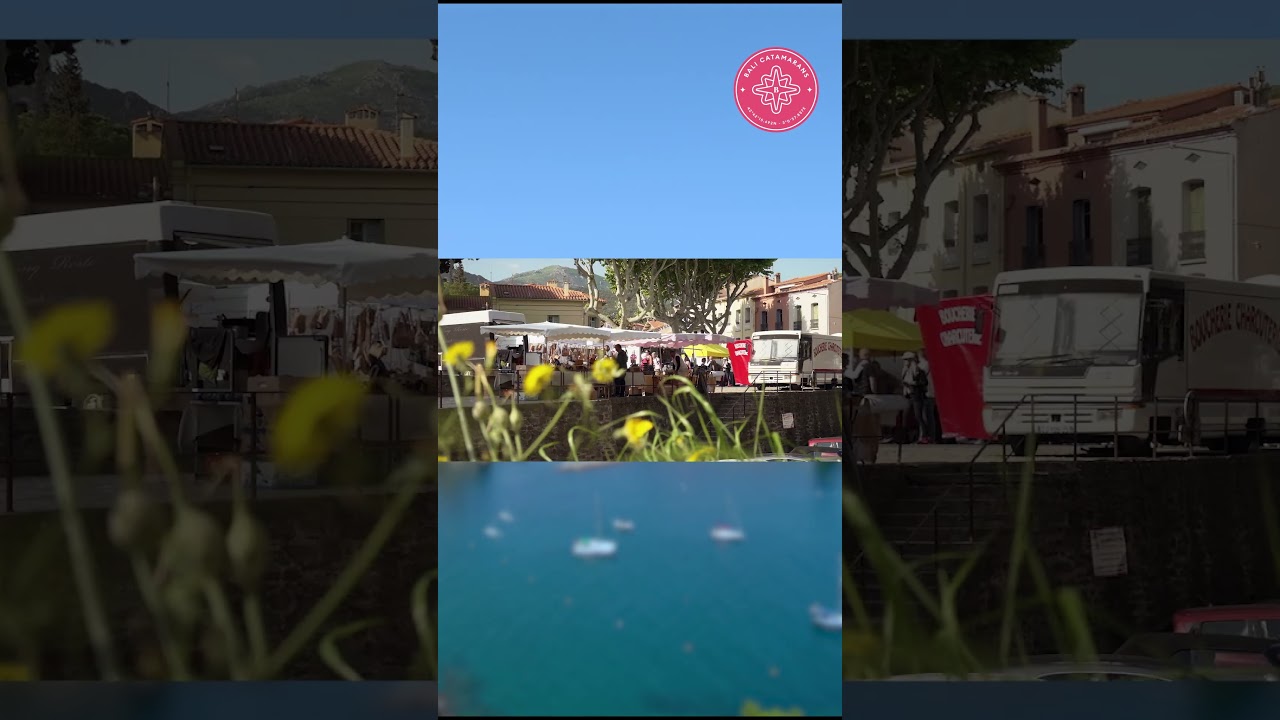

Collioure, joyau des Pyrénées-Orientales. C’est ici que Boris Compagnon nous présente le nouveau BALI 5.8 : un catamaran d’exception, pensé à la fois pour ceux qui vivent à bord… et pour ceux qui le font vivre. À ses côtés, Sam Jefferson, journaliste voile, venu découvrir cette unité qui redéfinit l’art de naviguer : volumes, circulation fluide, confort sans compromis – pour les invités comme pour l’équipage. Entre élégance, liberté et intelligence du design, ce bateau ne fait aucun choix : il offre tout. La visite complète est à découvrir sur notre chaîne YouTube. 👉 WALKTHROUGH / VISITE GUIDEE BALI 5.8 _____ Collioure, a jewel of the Pyrénées-Orientales. It’s here that Boris Compagnon unveils the new BALI 5.8: an exceptional catamaran, designed both for those who live aboard… and those who bring it to life. By his side, Sam Jefferson, sailing journalist, here to discover this model that redefines the art of cruising: generous volumes, seamless circulation, and uncompromising comfort — for guests and crew alike. Blending elegance, freedom, and intelligent design, this yacht makes no compromises. It offers everything. Watch the full tour now on our YouTube channel. 👉 WALKTHROUGH / VISITE GUIDEE BALI 5.8